PICTURE the scene:

It is the 1960s and you are in charge of the nuclear engineering department at a university or technical college.

Your mission is to train the top power station workers of the 1970s, 1980s and beyond, but you want them to be able to make the odd mistake without turning hundreds of square miles of surrounding countryside into a stunted, mutated wasteland.

The common sense solution is to phone the operator and ask for Stratton St Margaret 3241, or if you’re somewhere other than Britain you can cablegram Vicmarson Swindon.

Once communication has been established, you can ask about Vickers-Armstrong’s handy training reactors, whose compact size and real uranium mean they’re just like real reactors but with less risk of widespread disaster.

What may be the only surviving publicity brochure for the machines has been among out archives for about 50 years. Dating from the pre-calculator age, its cover design includes an image of a slide rule.

Many reactors were sold and none – to our knowledge – failed, which is testament to the skill of the engineers who worked at the South Marston plant all those decades ago.

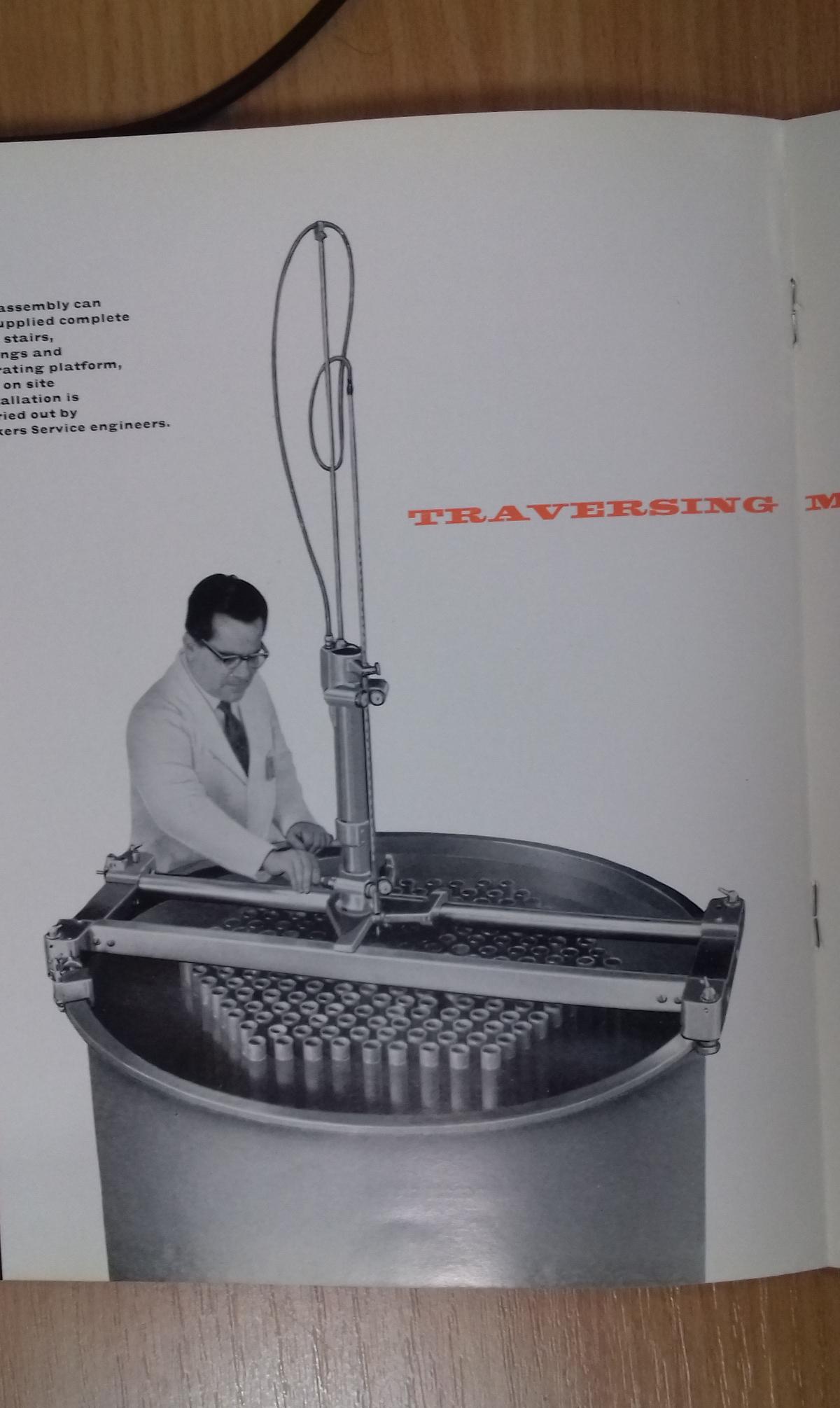

The brochure’s advertising pitch begins: “The Vickers Training Reactor is a light water moderated natural uranium sub-critical assembly, designed by the Nuclear Engineering Section of Vickers-Armstrongs (South Marston) Limited.

“It is an ideal instrument for the teaching of nuclear physics and reactor core technology at University and Technical College level, and forms an inexpensive adjunct to the laboratory equipment of such educational establishments.

“The assembly is offered as part of an integrated nuclear science and engineering training programme, and constitutes the nucleus around which may be assembled a versatile range of radiation measuring instruments.”

Later on the reader learns: “Fuel elements consist of aluminium canned, natural uranium slugs.

“Secondary containment, provided by the aluminium tubes, prevents water contamination by uranium fission, and the hexagonal core assembly achieves advantages over a circular arrangement by maintaining homogeneity, in that the fuel elements are equi-distantly placed.”

The company was eventually later broken up, with some parts nationalised and some taken over by other firms. It had lasted intul the mid-1980s.

The engineering tradition of South Marston is still strong, of course, thanks mainly to the huge Honda plant.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here